Target Value Design in a Construction Management Setting

The Value Proposition

August 28, 2018All this talk about tariffs and our busy construction market brings about fears for owners, designers and builders alike. The dreaded re-design of overbudget projects after each milestone estimate is a morale buster for everyone, but more importantly it wastes precious time.

What if we could work differently?

Instead of design, estimate, value engineering (VE), and then redesign, we believe there are some Integrated Product Delivery (IPD) tools that should be leveraged to achieve our owners’ budgets. Target Value Design, Value Add (VA) Logs, Risk Logs, and Last Responsible Moment decisions allow teams to streamline the design process. What’s great about these tools is that they don’t rely on any one form of agreement or the formation of a big room in order to work. They can apply to many of our projects today, and if embraced, they can improve the design process and make it more efficient for all involved. In this blog, we will focus on the advantages of Target Value Design and the VA Log.

Target Value Design

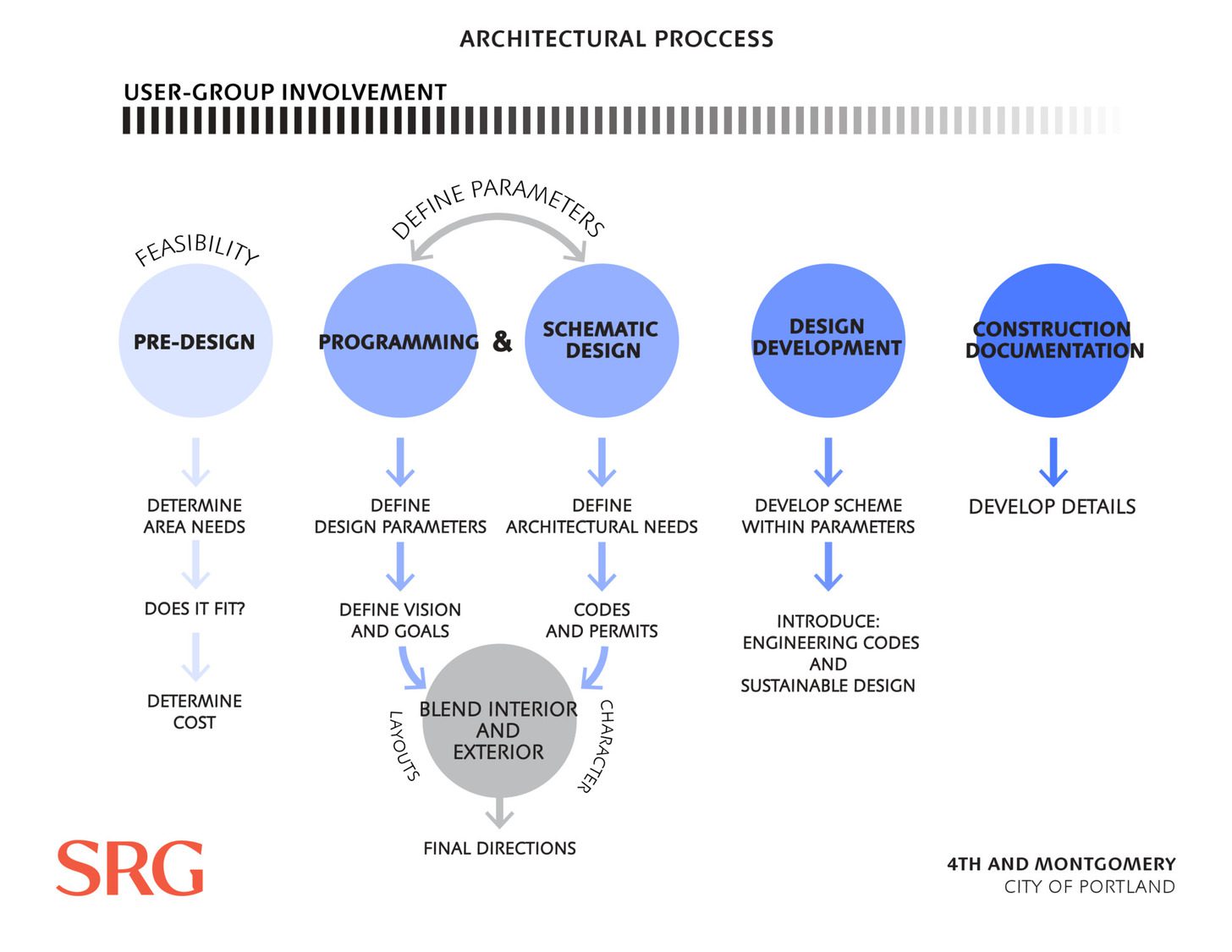

Target Value Design is, simply put, a way to break the project budget into smaller buckets of money and then designing to meet the smaller buckets. You begin with the estimate – not with the design. The early involvement of cost estimators is required, and ideally the CM and trade partners inform design decisions. The initial estimate is based on data from similar building types and regional metrics to generate a baseline estimate for the project. The owner, architect and estimator should accommodate any project nuances; for example, the need to get through a Land Use Hearing which might raise the bar for envelope performance or the need for technical spaces requiring specialized systems.

Once the basics are understood, the overall budget is broken down into typical building components which might include up to a dozen different buckets for budget allocation: envelope, site, structure, wet side mechanical, dry side mechanical, electrical, low voltage, and interior. Once the money is allocated for each bucket, the team goes to work designing each component of the building without exceeding the budget of each individual bucket.

A few important items to keep in mind:

- The targets should be a stretch but not impossible. If they are impossible, the team may give up on the process, not taking it seriously.

- The team should agree on the targets together with the owner.

- The targets should be set prior to programming discussions with the building occupants. Programming discussions should be based on what the budget can support.

- When the team learns more at traditional milestones, periodic adjustments to buckets can and should be made – shifting money as the design requires.

- The owner should help manage scope creep and have confidence in the process as he/she is an important member of the team and key to success.

The Fourth and Montgomery Project is a partnership with four owners who each have a stake in the project which will house the PSU Graduate School of Education, the OHSU | PSU School of Public Health, the PCC Dental Programs, and The City of Portland Bureau of Planning and Sustainability. Each owner provides a liaison to participate in the process. PSU is also providing the project management by utilizing a Construction Manager/General Contractor (CM/GC) contract with Andersen Construction and a design contract with SRG Partnership. Nearing the close of the Schematic Design phase, the team onboarded several trade partners in a collaborative delivery modeled after IPD to deliver value to the design process. During that time, the roughly $77M project was over the target by approximately 15% with an owner mandate – no program cuts.

The Value Add Log: Find Savings and Add Value

Our clients for Fourth and Montgomery wanted this building to provide a high-performance radiant mechanical system with a Dedicated Outside Air System (DOAS.) The team had done a deep analysis and used Choosing By Advantage (CBA) to provide a series of data points and engaged the owners to weigh in on their priorities to evaluate several mechanical system options.

The outcome of this analysis was that the radiant system with DOAS provided the most value. However, in order to offer this value, the team needed to find $11M of savings elsewhere. After evaluating traditional VE lists, the team could eliminate 5% of our budget issues, which still left us with a 10% problem; in other words, we needed to find a way to save another $7.5M.

How would we find the savings we needed without cutting the mechanical system design?

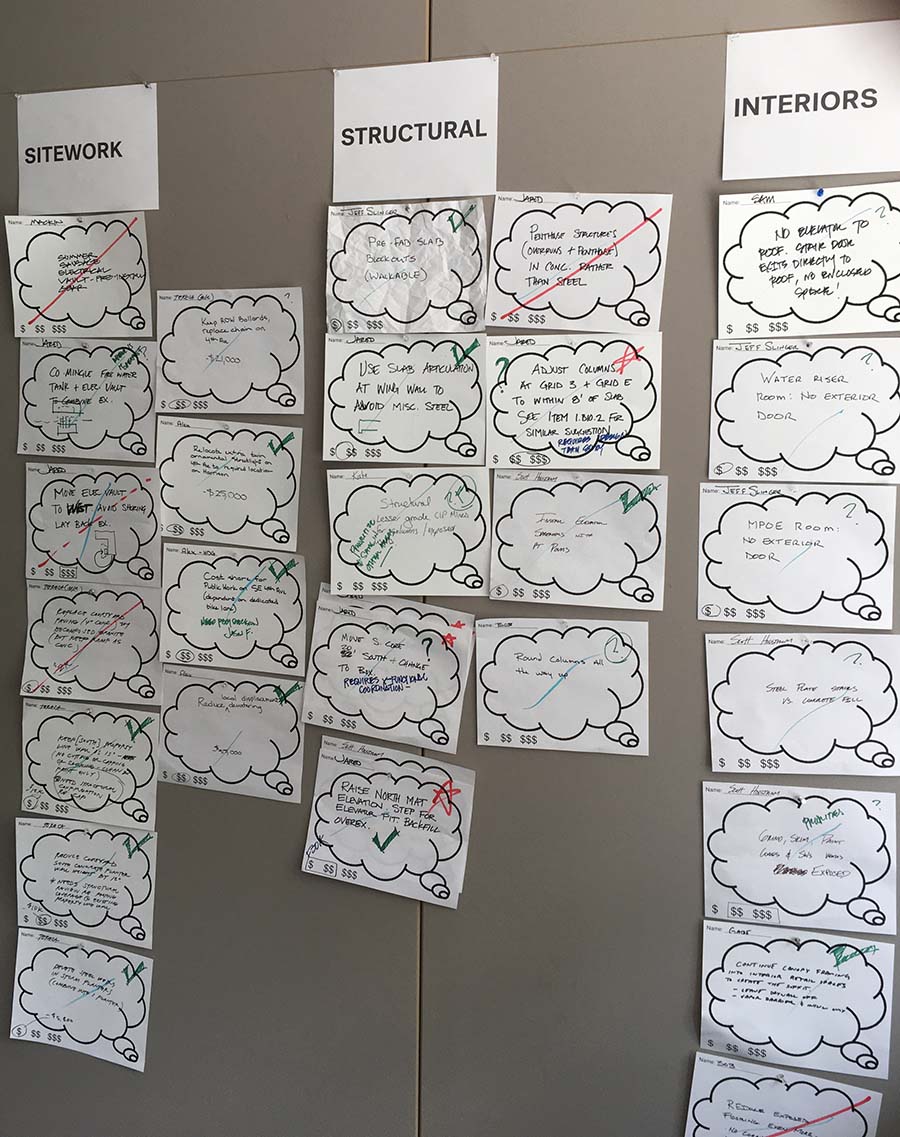

We decided to have a 2-day Value Summit.

Day 1: MEP and InteriorsDay 2: Site, Structure and Envelope

We invited all architects, owners, design consultants, owner’s consultants, general contractors and trade partners. Idea bubbles were the format. No idea is a bad idea: big, small, outside the box, just keep them coming! We wanted to create a fun meeting and a safe space for ideas. The team came up with some great innovations. Panelizing the skin, installing the underground fire protection tanks using a fiberglass tank that is better suited to our site excavation requirements, and providing two small, precast vaults in lieu of one large cast-in-place vault were just a few of the ideas. At the end of the 2-day summit, the team came up with 152 ideas which resulted in $4.2M in additional savings. Now we were on the right track. It was enough to give our owners the confidence they needed to pull the trigger on the mechanical system of their choice, thereby adding value to the project.

We are currently in the final stages of Design Development, and the team is continuing to apply the pressure to find the remaining $3.3M in savings.

At the end of September, we hope to have another milestone estimate within reach of the total project budget. We will be through our Land Use Review process with the City of Portland, mitigating one of our larger risks, and will …fingers crossed… hopefully be closer to our targets and able to focus on finalizing the design and coordinating documents.

No one person, no one firm is responsible. This effort has truly put the integrated in IPD. Everyone is united in the mission of the project, and they are engaged in a team culture which supports innovative solutions. We are weathering a busy construction economy, and I’m inspired by the creative solutions we’ve managed to develop along the way.